Electric mining vehicles and fast battery chargers are set to offer safer and more sustainable mining in Africa

Becker Mining South Africa has been appointed distributors in Southern and Central Africa by Miller Technology, a leading mobile mining equipment supplier. Becker Mining SA now supplies and supports Miller’s new range of Relay electric mining vehicles, which has been developed especially for the underground mining environment.

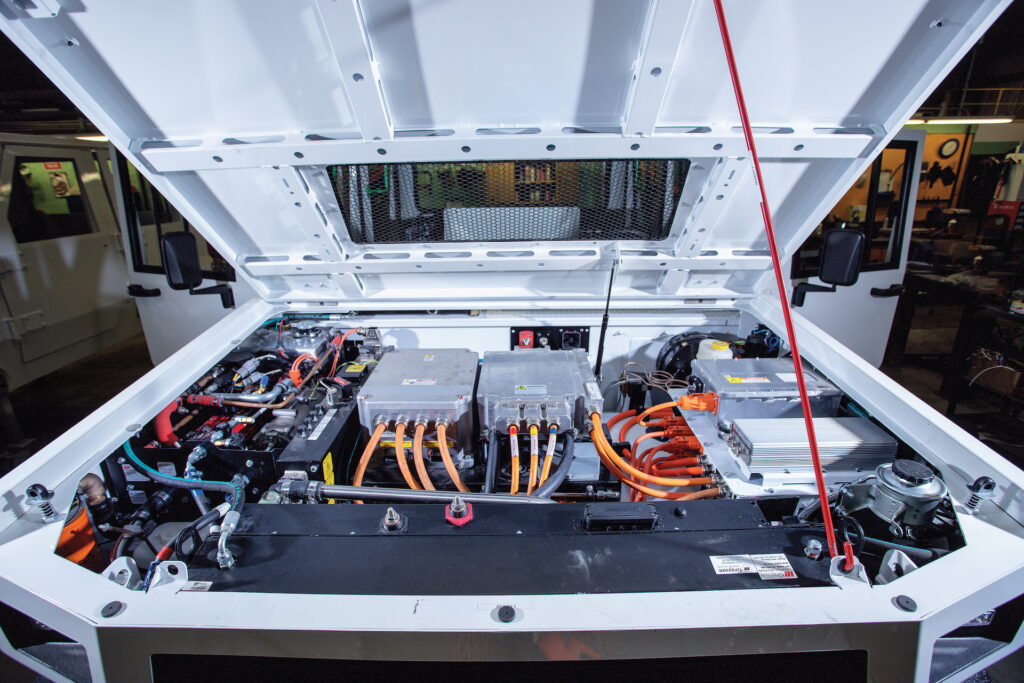

The Relay electric mining vehicle has been custom designed with an advanced battery management system that makes this one of the most environmentally safe and efficient light duty mining vehicles of its kind available today.

“Becker Mining Australia and Miller Technology have teamed up recently on a project in Australia, to help reduce the mining sector’s greenhouse gas emissions and we are proud to now be part of this initiative in Africa. The Becker Mining team is also committed to contributing to a safer and more sustainable mining environment,” explains Nico de Lange, Senior General Manager, Energy Sales, Becker Mining South Africa. “Miller Technology has designed and produced vehicles in Canada for over 40 years, for specific mining applications. In an initiative to develop new technologies for cleaner and safer mining, the company has extended the development of its Battery Electric Vehicle (BEV) technology, with the recent launch of the Relay BEV, which is now available in Africa from Becker Mining SA.

“The Relay is a new fully electric mining vehicle – purpose-designed for the mining sector -with a durable and modular construction and features for easy control and serviceability. This robust vehicle provides 1,550 Nm of torque and can safely carry a two-ton payload, with a maximum operating speed of 110 km/h, that is software programmable.”

The Relay has an advanced Rechargeable Energy Storage System (RESS) and is capable of being fully charged in less than 20 minutes, for a 10-hour mining shift. If the topology of the mine is suitable, regenerative braking technology offers up to two hours of additional operating time.

The Relay is designed for on-board and off-board charging, through a Combined Charging System (CCS) type 2 – one of the most convenient and widely adopted charging standards. These chargers are liquid cooled, with an IP65 rated enclosure that is sealed to protect the power electronics against dust and moisture. Modifications – including additional safety and enhanced filtration features – have been made, to improve performance in harsh mining conditions.

This electric mining vehicle also offers reduced noise levels and advanced cooling and temperature monitoring capabilities. Other notable features for high performance and greater safety include fire suppression systems, programmable zone control facilities, integrated onboard diagnostics and comprehensive on-board data logging, with bidirectional data transfer via Wi-Fi or LTE networks.

The Relay’s intrinsically safe methane monitoring system initially analyses for methane. If results are clear, the vehicle’s 24 V system is energised, enabling pre-start diagnostics. If methane is detected during service, the system will default back to the intrinsically safe system.

These electric mining vehicles are fitted with puncture-resistant segmented rubber tyres, with an open construction. In the event of shredded segments, each damaged segment can be replaced, without having to remove the rim.

Becker Mining South Africa, which is committed to the highest standards in quality and safety in the mining sector, has a fully trained service team that supports these new electric mining vehicles and charging units throughout Africa.

This new equipment enhances the company’s extensive product portfolio, which comprises high-performance, fit-for-purpose transportation, energy, automation and communication systems for underground and surface mining installations. Becker Mining also offers intrinsically safe (IS) and flameproof underground electrical reticulation products, as well as fluid transfer, rigging, rope attachment, steel arch tunnel support and chairlift solutions. An important feature of all systems is they are designed to facilitate future upgrades.

For further information Nico de Lange | Senior General Manager, Energy Sales, Becker Mining South Africa

PO Box 124185, Alrode, 1451

Telephone (011) 617 6300

Email info@za.becker-mining.com

Released by Lindy Morton, Festivitas 083 268 6666 festivitas@dbnmail.co.za

October 2021